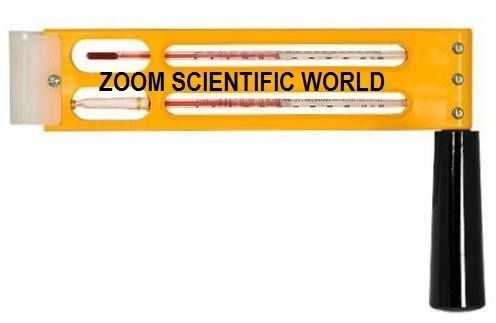

Cloud And Pour Point Apparatus

Product Details:

- Usage Industrial

- Product Type Apparatus

- Color Golden

- Voltage 220 Volt (v)

140 INR/Unit

X

Cloud And Pour Point Apparatus Price And Quantity

- 140 INR/Unit

- 1 Unit

- IS 1448, ASTM D97

- 6 Test Jars

- Approx. 15 kg

- Up to 6 samples per test

- Immersion type cooling

- Manual Plunger

Cloud And Pour Point Apparatus Product Specifications

- Golden

- Apparatus

- 220 Volt (v)

- Industrial

- IS 1448, ASTM D97

- 6 Test Jars

- Approx. 15 kg

- Up to 6 samples per test

- Immersion type cooling

- Manual Plunger

Cloud And Pour Point Apparatus Trade Information

- Cash Advance (CA), Cash in Advance (CID)

- 10 Unit Per Week

- 1 Week

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Western Europe, Middle East, Central America, Eastern Europe, South America, Asia, North America, Australia, Africa

- All India

Product Description

Cloud And Pour Point Apparatus

This is made as a specified the pour point is the lowest temperature at which the oil will just fail to flow. The apparatus consists of a main cooling bath made of stainless steel sheet and stand unit with drain plug and cover with provision for fitting thermometer and a filling aperture for adding freezing mixture. A glass jar for containing oils, jacket, disc and gasket as specified are also provided.

Reliable Determination of Pour and Cloud Points

This apparatus is engineered for precise determination of petroleum product pour and cloud points, supporting critical decisions in product quality and usability. It efficiently cools and processes up to six samples in parallel, strictly adhering to international (ASTM D97) and Indian (IS 1448) testing standards for dependable, repeatable results.

User-Friendly Design and Robust Construction

Featuring an immersion cooling system and a stable construction weighing about 15 kg, the device is both durable and practical. Its design promotes efficient workflow by allowing simultaneous testing of multiple samples, making it a staple for laboratories, manufacturers, and quality control departments in the petroleum industry.

FAQs of Cloud And Pour Point Apparatus:

Q: How does the Cloud and Pour Point Apparatus work?

A: The apparatus uses an immersion-type cooling bath to gradually reduce the temperature of petroleum samples in up to six test jars. By observing when the samples first show cloudiness (cloud point) and when they cease to flow (pour point), accurate temperature readings are obtained as per industry standards.Q: What testing standards does this apparatus comply with?

A: It is designed to comply with IS 1448 (Indian Standard) and ASTM D97 (American Society for Testing and Materials Standard), ensuring globally recognized reliability and consistency in results.Q: When should I use the Cloud and Pour Point Apparatus?

A: This apparatus is utilized whenever you need to determine the pour and cloud points of petroleum products, such as lubricating oils, diesel, or other fuels, to assess their suitability for low-temperature applications.Q: Where can this apparatus be used?

A: It is ideal for deployment in testing laboratories, industrial quality control departments, research institutions, and manufacturing facilities dealing with petroleum and related products, especially in environments requiring compliance with IS 1448 and ASTM D97.Q: What is the process for conducting a test?

A: Prepare up to six samples and place them in the designated jars within the cooling bath. The apparatus gradually cools the samples while you monitor and record the temperature at which cloudiness appears (cloud point) and when flow stops (pour point) according to specified procedures.Q: What are the key benefits of using this apparatus?

A: It enables reliable, standardized evaluation of petroleum products performance at low temperatures, facilitating regulatory compliance and product quality assurance. Its multi-sample capacity enhances throughput, saving time for labs and manufacturers.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email